Ke hobane'ng ha re lokela ho plug the vias ho PCB?

E le hore ho finyelloe litlhoko tsa bareki, ka masoba ka boto potoloho lokela ho plugged.Ka mor'a ho itloaetsa ho hongata, mokhoa oa setso oa aluminium plug hole o fetoloa, 'me letlooa le lesoeu le sebelisetsoa ho tlatsa tjheseletsa ea ho hanyetsa le lesoba la plug ea boto ea potoloho, e ka etsang hore tlhahiso e tsitsitse le boleng bo ka tšeptjoang.

Via hole e phetha karolo ea bohlokoa ho hokahaneng ha lipotoloho.Le ntshetsopele ya indasteri ea elektronike, e boetse e khothalletsa ntshetsopele ya PCB, 'me e beha pele ditlhoko tse phahameng bakeng saHo etsoa le ho kopanya PCBthekenoloji.Theknoloji ea "hole plug" e bile teng, 'me litlhoko tse latelang li lokela ho finyelloa:

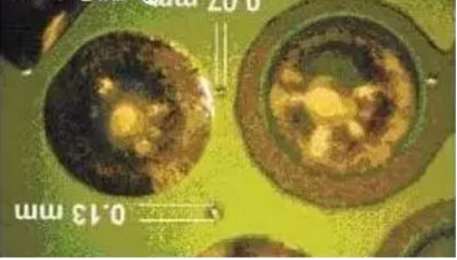

(1) Koporo e ka har'a lesoba e lekane, 'me mask a solder a ka hokeloa kapa che;

(2) Ho tlameha hore ho be le thini le loto ka lesoba la tsela, ka tlhokahalo e itseng ea botenya (4 microns), ha ho na solder e hanyetsang enke ka mokoting, e etsang hore lifaha tsa thini li patiloe ka mekoting;

(3) Ho tlameha ho be le lesoba la plug ea enke ka har'a lesoba la ka har'a lesoba, le sa bonahaleng, 'me ho se be le selikalikoe sa thini, lifaha tsa thini le sephara.

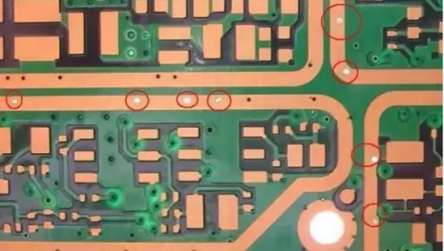

Ka nts'etsopele ea lihlahisoa tsa elektroniki ho ea ho "leseli, le tšesaane, le lekhutšoane le le lenyane", PCB le eona e nts'etsapele ho fihlela boima bo phahameng le bothata bo boholo.Ka hona, palo e kholo ea li-PCB tsa SMT le BGA li hlahile, 'me bareki ba hloka masoba a ho phunya ha ba kenya lisebelisoa, tse nang le mesebetsi e mehlano:

Ka nts'etsopele ea lihlahisoa tsa elektroniki ho ea ho "leseli, le tšesaane, le lekhutšoane le le lenyane", PCB le eona e nts'etsapele ho fihlela boima bo phahameng le bothata bo boholo.Ka hona, palo e kholo ea li-PCB tsa SMT le BGA li hlahile, 'me bareki ba hloka masoba a ho phunya ha ba kenya lisebelisoa, tse nang le mesebetsi e mehlano:

(1) E le ho thibela potoloho e khuts'oane e bakoang ke thini e phunyeletsang ka holim'a elemente nakong ea PCB holim'a soldering ea wave, haholo-holo ha re beha lesoba holim'a BGA pad, re tlameha ho qala ka ho etsa lesoba la plug ebe joale lesela la khauta ho thusa BGA soldering. .

(2) Qoba masalla a phallang ka har'a likoti;

(3) Ka mor'a holim'a thaba le motsoako oa karolo ea fektheri ea lisebelisoa tsa elektroniki, PCB e lokela ho monya vacuum ho theha khatello e mpe mochining oa tlhahlobo;

(4) Thibela solder ea holim'a metsi hore e se ke ea phalla ka mokoting, 'me e baka hore soldering ea bohata le ho ama thaba;

(5) thibela sefaha sa solder ho tsoa nakong ea solder ea maqhubu, le ho baka potoloho e khuts'oane.

Ho phethahala ha theknoloji ea plug hole bakeng sa ka lesoba

Bakeng saKopano ea SMT PCBboto, haholo-holo ho hlongoa ha BGA le IC, polaka ea via hole e tlameha ho ba sephara, khohoebekoane le concave e kopane kapa e tlose 1mil, 'me ho se be le thini e khubelu pheletsong ea lesoba;e le hore u finyelle litlhoko tsa bareki, mokhoa oa ho sebelisa sekoting oa ho sebelisa sekoti o ka hlalosoa e le multifarious, nako e telele ea ho phalla, ho laola mokhoa o thata, hangata ho na le mathata a kang ho theoha ha oli nakong ea mocheso oa moea o chesang le teko ea ho hanyetsa oli e tala le ho phatloha ha oli ka mor'a ho phekola.Ho latela maemo a sebele a tlhahiso, re akaretsa lits'ebetso tse fapaneng tsa plug hole tsa PCB, 'me re etsa papiso le tlhaloso e itseng ts'ebetsong le melemo le likotsi:

Tlhokomeliso: molao-motheo oa ho sebetsa ha moea o chesang ke ho sebelisa moea o chesang ho tlosa solder e feteletseng holim'a boto ea potoloho e hatisitsoeng le ka sekoting, 'me solder e setseng e koahetsoe ka ho lekana holim'a letlapa, melapo e sa thibang le lintlha tsa ho paka holim'a metsi. , e leng e 'ngoe ea litsela tsa ho phekola holim'a boto ea potoloho e hatisitsoeng.

1. Ts'ebetso ea lesoba ka mor'a hore moea o chesang o lekanngoe: ho tjheseletsa holim'a poleiti → HAL → lesoba la plug → ho phekola.Mokhoa oa ho se plugging o amoheloa bakeng sa tlhahiso.Kamora ho lekanngoa ha moea o chesang, skrine ea aluminium kapa skrine e thibelang enke e sebelisoa ho phethela plug ea liqhobosheane tsohle tse hlokoang ke bareki.Plug lesoba enke e ka ba photosensitive enke kapa thermosetting enke, tabeng ea ho etsa bonnete ba hore 'mala o tšoanang oa filimi metsi, plug lesoba enke molemo ka ho fetisisa ho sebelisa enke tšoanang le boto.Tshebetso ena e ka etsa bonnete ba hore lesoba le phunyeletsang le ke ke la theola oli ka mor'a hore moea o chesang o lekanngoe, empa ho bonolo ho etsa hore enke ea lesoba la plug e silafatse bokaholimo ba poleiti le ho se lekane.Ho bonolo ho bareki ho baka soldering ea bohata nakong ea ho kenya (haholo-holo BGA).Kahoo, bareki ba bangata ha ba amohele mokhoa ona.

2. Ts'ebetso ea lesoba pele ho boemo ba moea o chesang: 2.1 plug lesoba le lakane ea aluminium, tiisa, sila poleiti, ebe u fetisetsa litšoantšo.Ts'ebetso ena e sebelisa mochini oa ho phunya oa CNC ho phunya letlapa la aluminium le hlokang ho phunngoa lesoba, ho etsa poleiti ea skrineng, lesoba la plug, ho netefatsa hore lesoba la polaka le tletse, enke ea lesoba la plug, enke ea thermosetting le eona e ka sebelisoa.Litšobotsi tsa eona e tlameha ho ba boima bo phahameng, phetoho e nyane ea shrinkage ea resin, le ho khomarela hantle ka lebota la lesoba.Ts'ebetso ea thekenoloji ke ka tsela e latelang: pretreatment → plug lesoba → grinding plate → phetisetso ea paterone → etching → plate surface resistance welding.Mokhoa ona o ka etsa bonnete ba hore lesoba la polaka ea lesoba le boreleli, 'me boemo ba moea o chesang bo ke ke ba ba le mathata a boleng joalo ka ho phatloha ha oli le ho theoha ha oli moeling oa lesoba.Leha ho le joalo, ts'ebetso ena e hloka ho teteka ha nako e le 'ngoe ea koporo ho etsa hore botenya ba koporo ba lebota la lesoba bo finyelle maemo a moreki.Ka hona, e na le litlhoko tse phahameng tsa ho roala ha koporo ea poleiti eohle le ts'ebetso ea grinder ea poleiti, e le ho etsa bonnete ba hore resin e holim'a koporo e tlosoa ka ho feletseng, 'me bokaholimo ba koporo bo hloekile ebile ha boa silafala.Lifeme tse ngata tsa PCB ha li na ts'ebetso ea koporo e teteaneng ka nako e le 'ngoe, mme ts'ebetso ea lisebelisoa ha e khone ho fihlela litlhoko, ka hona ts'ebetso ena ha e sebelisoe hangata lifemeng tsa PCB.

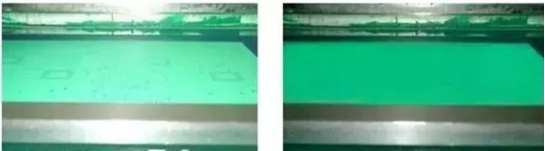

(The blank silk screen) (The stall point film Net)

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. For more information, please email to service@pcbfuture.com.

Nako ea poso: Jul-01-2021