1. Ho roala menoana

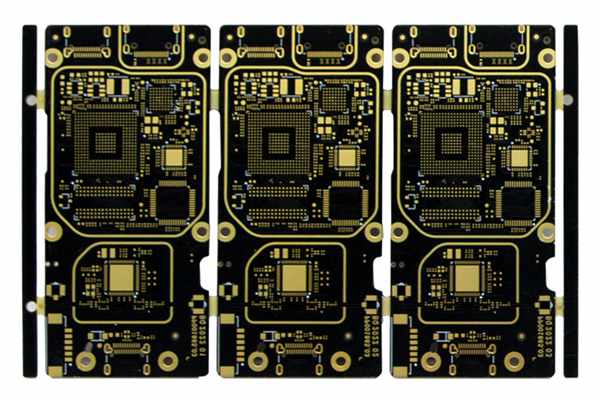

In Setšoantšo sa PCB, litšepe tse sa tloaelehang li pentiloe holim'a sehokelo sa moeli oa boto, moeli oa boto o hlahelletseng kapa monoana oa khauta ho fana ka khanyetso e tlase ea ho ikopanya le khanyetso e phahameng ea ho roala, e bitsoang ho penta ha menoana kapa ho pharalla ha sebaka.Mokhoa ona o tjena:

1) ebola lesela 'me u tlose thini kapa lesela la loto holim'a khokahanyo e hlahelletseng.

2) ho hlatsoa ka metsi.

3) hohla ka abrasive.

4) activation diffuse in 10% sulfuric acid.

5) botenya ba nickel plating ha bo kopana bo hlahelletseng ke 4-5 μ m.

6) Hloekisa ho tlosa metsi a diminerale.

7) ho lahla tharollo ea ho noa khauta.

8) ho roala khauta.

9) ho hloekisa.

10) ho omisa.

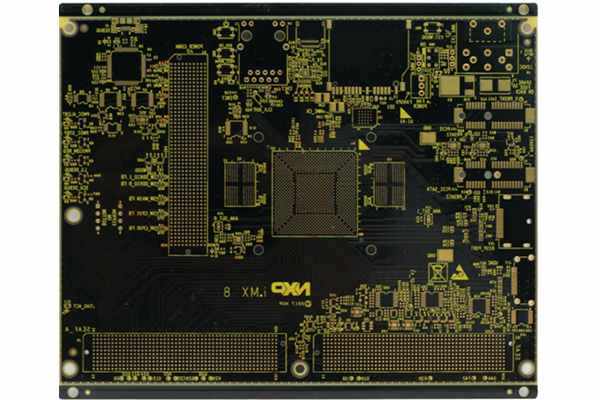

2. Ka plating

Ho na le mekhoa e mengata ea ho theha lera le tšoanelehang la electroplating leboteng la lesoba la ho phunya substrate, le bitsoang ts'ebetso ea lerako la lesoba lits'ebetsong tsa indasteri.Ts'ebetso ea tšebeliso ea khoebo ea potoloho ea eona e hatisitsoeng e hloka litanka tse ngata tsa polokelo tse mahareng, tseo e 'ngoe le e' ngoe e nang le litlhoko tsa eona tsa taolo le tlhokomelo.Via electroplating ke mokhoa o latelang o hlokahalang oa tlhahiso ea ts'ebetso ea ho cheka.Ha boro bo phunya ka har'a foil ea koporo le karolo e ka tlase ea eona, mocheso o hlahisoang o kokobetsa resin ea maiketsetso e etsang karolo e kholo ea karoloana, 'me resin e khutsitsoeng le litšila tse ling tsa ho cheka li bokellana ho potoloha lesoba ebe li apesoa leboteng la lesoba le sa tsoa pepesoa. ka foil ea koporo, 'me resin e tsitsitseng e tla boela e tlohe lera la axis e chesang leboteng la lesoba la substrate;E bonts'a ho khomarela ho fokolang ho li-activator tse ngata, tse hlokang nts'etsopele ea mofuta oa theknoloji e ts'oanang le ts'ebetso ea lik'hemik'hale ea ho tlosa letheba le ho khutlela morao.

Mokhoa o loketseng haholoanyane bakeng sa bopaki ba PCB ke ho sebelisa enke e etselitsoeng ka ho khetheha e nang le viscosity e tlase, e nang le sekhomaretsi se matla 'me e ka hokahanngoa habonolo le marako a lesoba a chesang haholo, ka hona ho tlosa mohato oa ho khutlela morao.

3.Roller e kopantsoeng le plating e khethiloeng

Lithako le likhokahano tsa likarolo tsa elektronike, tse kang li-connectors, li-circuits tse kopantsoeng, li-transistors le li-circuits tse hatisitsoeng tse feto-fetohang, li khethoa ka mokhoa o ikhethileng ho finyella khanyetso e ntle ea ho kopana le ho hanyetsa kutu.Mokhoa ona oa electroplating e ka ba oa letsoho kapa oa othomathike.Ho bitsa chelete e ngata haholo ho emisa ho khetha pini e 'ngoe le e 'ngoe ka bonngoe, kahoo ho lokela ho sebelisoa welding.Ha u khetha mokhoa oa ho roala, qala ka ho roala filimi ea inhibitor likarolong tsa tšepe ea koporo ea tšepe e sa hlokeng electroplating, 'me u emise feela electroplating holim'a foil e khethiloeng ea koporo.

4.Brush plating

Brush plating ke theknoloji ea electrostacking, e emisang feela electroplating sebakeng se lekanyelitsoeng mme ha e na tšusumetso likarolong tse ling.Hangata, litšepe tse sa tloaelehang li kenngoa likarolong tse khethiloeng tsa boto ea potoloho e hatisitsoeng, joalo ka libaka tse kang lihokelo tsa boto.Brush plating e sebelisoa haholo holithupelo tsa kopano ea elektronikiho lokisa liboto tsa potoloho ea litšila.

PCBFuture e hahile botumo ba rona bo botle indastering ea tšebeletso ea kopano ea PCB e felletseng bakeng sa kopano ea mohlala ea PCB le molumo o tlase, kopano ea PCB ea bohareng.Seo bareki ba rona ba hlokang ho se etsa ke ho romella lifaele tsa moralo oa PCB le litlhoko ho rona, 'me re ka hlokomela mosebetsi o setseng.Re na le bokhoni bo felletseng ba ho fana ka lits'ebeletso tse ke keng tsa qojoa tsa PCB empa re boloka litšenyehelo tsohle ka har'a tekanyetso ea hau.

Haeba u batla moetsi oa kopano ea Turnkey PCB ea loketseng, ka kopo romella lifaele tsa hau tsa BOM le lifaele tsa PCB ho sales@pcbfuture.com.Lifaele tsohle tsa hau li lekunutu haholo.Re tla u romella quote e nepahetseng ka nako ea ho etella pele ka lihora tse 48.

Nako ea poso: Dec-13-2022