Na o tlaKopano ea PCBboto e be kotsi ho 'mele oa motho?Metsoalle e mengata e kileng ea etela workshop e tla botsa lipotso tse joalo.Kajeno ke tla u fa karabo!Ho kotsi ho sebetsa nako e telele tikolohong ea boto ea PCB.Tšilafalo ea kopano ea PCB e bua ka li-depositi leha e le life tse holim'a metsi, litšila, li-slag inclusions le li-adsorbents tse fokotsang lik'hemik'hale, thepa ea 'mele kapa ea motlakase ea PCBA ho ea maemong a sa tšoaneleheng.

Likotsi tsa tšilafalo ea PCBA, tse ka lebisang ka kotloloho kapa ka tsela e sa tobang ho kopano ea PCB likotsi tse ka bang teng, mohlala:

1. The organic acid ka masala tla corrode PCBA;

2. Nakong ea ts'ebetso ea matla, li-ion tse setseng li baka electromigration ka lebaka la phapang e ka 'nang ea e-ba teng pakeng tsa manonyeletso a solder, e leng se fellang ka ho hlōleha ha nako e khutšoanyane ea sehlahisoa;

3. Masala a ama phello ea ho roala;

4. Ka mor'a liphetoho tsa nako le mocheso oa tikoloho, ho phunyeha le ho phunya ha ho roala ho tla baka mathata ka ho tšepahala ha sehlahisoa.

Tšilafalo ea kopano ea PCB e bua ka litšila leha e le life tse holim'a metsi, li-deposit, li-adsorbents le li-slag inclusions tse fokotsang lik'hemik'hale, thepa ea 'mele kapa ea motlakase ea PCBA ho ea maemong a sa tšoaneleheng.E le ho ntlafatsa botšepehi le boleng ba lihlahisoa tsa elektronike, ho hlokahala ho laola ka thata ho ba teng ha masala nakong ea ts'ebetso ea kopano ea PCB, 'me litšila tsena li tlameha ho tlosoa ka ho feletseng ha ho hlokahala.

Tšilafalo ea kopano ea PCB haholo-holo e kenyelletsa lintlha tse latelang:

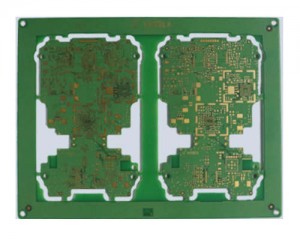

1. Tšilafalo ea bokaholimo ba PCB e tla bakoa ke tšilafalo kapa oxidation ea likarolo tsa kopano ea PCB leLiboto tsa potoloho tsa PCB;

2. Ho tla hlahisoa ka letsoho ho tla hlahisoa likhatiso tsa menoana, 'me ho tla hlahisoa wave soldering trace ea Wave soldering le tray ea Welding (fixture).Ho ka 'na ha e-ba le mefuta e meng ea litšila holim'a kopano ea PCB ka likhato tse sa tšoaneng, tse kang plugging glue, mocheso o phahameng oa masala a sekhomaretsi, menoana le lerōle;

3. Ts'ebetsong ea kopano ea PCB, ho hlokahala hore u sebelise peista ea solder, terata ea welding bakeng sa welding.Flux e tla hlahisa masala nakong ea ts'ebetso ea soldering, e silafatsa bokaholimo ba boto ea kopano ea PCB, 'me ke eona e silafatsang ka sehloohong;

4. Tšilafalo ea motlakase e bakoang ke lerōle, metsi le mosi o qhibilihisang, mouoane, lintho tse phelang le likaroloana tse lefshoang tse khomaretsoeng kopanong ea PCB mosebetsing.

Re na le tšepo ea ho u fa motsoako o motle ka ho fetisisa oa ts'ebeletso ea kopano ea PCB, boleng, theko le nako ea ho fana ka taelo ea kopano ea PCB ea batch e nyane le odara ea kopano ea Mid batch Volume PCB.

Haeba u batla e loketsengMoetsi oa kopano ea PCB, ka kopo romella lifaele tsa hau tsa BOM le lifaele tsa PCB hosales@pcbfuture.com.Lifaele tsohle tsa hau li lekunutu haholo.Re tla u romella quote e nepahetseng ka nako ea ho etella pele ka lihora tse 48.

Nako ea poso: Aug-09-2022