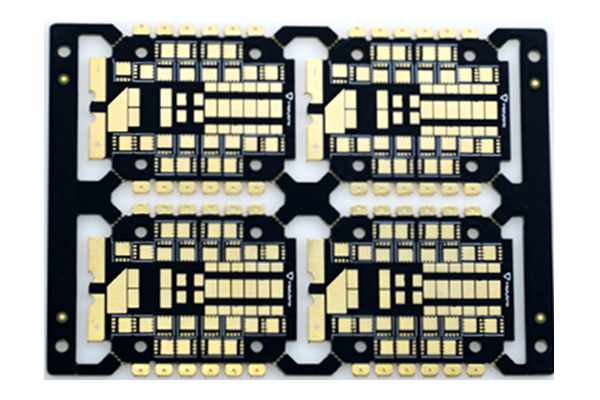

1. Ho lekanngoa ha solder ea moea o chesang

Boto ea silevera e bitsoa tin hot air solder leveling board.Ho fafatsa lesela la thini karolong e ka ntle ea potoloho ea koporo ho tsamaisana le ho cheselletsa.Empa e ke ke ea fana ka ts'epo ea nako e telele ea ho ikopanya joalo ka khauta.Ha e sebelisoa nako e telele haholo, e bonolo ho oxidize le mafome, e bakang ho se kopane hantle.

Melemo:Theko e tlase, ts'ebetso e ntle ea welding.

Mefokolo:Bokaholimo ba boto ea ho tsamaisa solder bo bobe, bo sa lokeleng lithakhisa tse nang le lekhalo le lenyane le likaroloana tse nyane haholo.Lifaha tsa thini li bonolo ho hlahisaTs'ebetso ea PCB, e leng bonolo ho baka potoloho e khutšoanyane ho likarolo tse nyenyane tsa lekhalo la lekhalo.Ha e sebelisoa ts'ebetsong ea SMT e nang le mahlakore a mabeli, ho bonolo haholo ho fafatsa thini e qhibiliha, ho fella ka lifaha tsa thini kapa matheba a chitja, e leng se bakang ho se leka-lekane ho feta le ho ama mathata a ho cheselletsa.

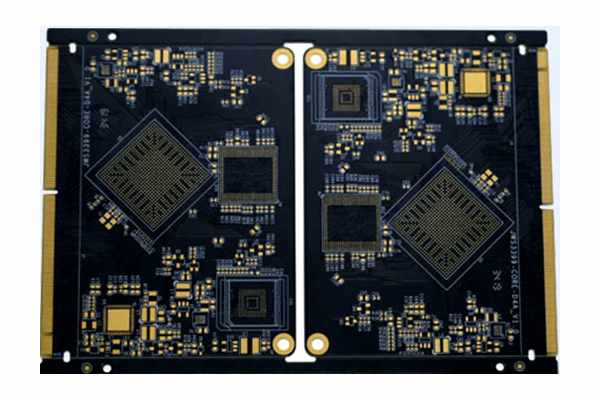

2, silevera e qoelisoang

Mokhoa oa silevera oa ho qoelisoa o bonolo ebile o potlakile.Silivera ea ho qoelisoa ke karabelo ea ho falla, hoo e batlang e le sekoaelo sa silevera sa submicron (5 ~ 15 μ Ka, hoo e ka bang 0.1 ~ 0.4 μ m) Ka linako tse ling mokhoa oa ho qoelisoa ka silevera o boetse o na le lintho tse ling tsa manyolo, haholo-holo ho thibela ho bola ha silevera le ho felisa bothata. Leha e ka pepesetsoa mocheso, mongobo le tšilafalo, e ntse e ka fana ka thepa e ntle ea motlakase le ho boloka matla a ho chesehela, empa e tla lahleheloa ke khanya.

Melemo:Sebaka sa silevera se kentsoeng ka tjheseletsa se na le weldability e ntle le coplanarity.Ka nako e ts'oanang, ha e na litšitiso tse tsamaisang joaloka OSP, empa matla a eona ha a tšoane le khauta ha e sebelisoa e le sebaka sa ho kopana.

Mefokolo:Ha e pepesehetse tikolohong e metsi, silevera e tla hlahisa ho falla ha elektronike tlas'a ketso ea motlakase.Ho eketsa likarolo tsa organic ho silevera ho ka fokotsa bothata ba ho falla ha elektronike.

3, Lekotikoti la ho qoelisoa

Lesenke la ho qoelisoa le bolela ho roala ka solder.Nakong e fetileng, PCB e ne e tloaetse litelu tsa tin ka mor'a ts'ebetso ea tin.Litelu tsa thini le ho falla ha thini nakong ea ho cheselletsa ho tla fokotsa ho tšepahala.Ka mor'a moo, li-additives tsa manyolo li kenngoa ho tharollo ea ho qoelisoa ka thini, e le hore mohaho oa tin o be granular, o hlōlang mathata a fetileng, hape o na le botsitso bo botle ba mocheso le weldability.

Mefokolo:Bofokoli bo boholo ba ho qoelisoa ka masenke ke bophelo ba eona bo bokhutšoanyane ba ts'ebeletso.Haholo-holo ha li bolokiloe mocheso o phahameng le tikoloho ea mongobo o phahameng, metsoako pakeng tsa tšepe ea Cu / Sn e tla tsoela pele ho hōla ho fihlela e lahleheloa ke solderability.Ka hona, lipoleiti tse kentsoeng ka thini li ke ke tsa bolokoa nako e telele haholo.

Re na le tšepo ea ho u fa motsoako o motle ka ho fetisisa oatšebeletso ea kopano ea turnkey PCB, boleng, theko le nako ea ho fana ka taelo ea kopano ea hau ea Small batch ea PCB le taelo ea kopano ea Mid batch Volume PCB.

Haeba u batla e loketseng PCB kopano moetsi, ka kopo romela difaele tsa hao BOM le PCB difaele hosales@pcbfuture.com.Lifaele tsohle tsa hau li lekunutu haholo.Re tla u romella quote e nepahetseng ka nako ea ho etella pele ka lihora tse 48.

Nako ea poso: Nov-21-2022